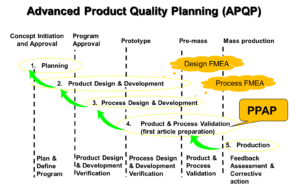

Advance Product Quality Planning (APQP / New Product Introduction System for IATF and ISO compliance

Challenges :

Advance Product Quality Planning (APQP) / NPI can be complex, involving the management of multiple tasks and production of multiple documents. With so many interconnected elements it’s important to manage the process efficiently and maintain visibility, ensuring quality management within the supply chain.

It is not enough for the goal to be: bring a product to market. The goal should be to bring a product to market successfully. This requires guarding profit margins by understanding the requirements and a reliable manufacturing process that delivers the product on time.

Other than the above mentioned challenges encountered by most of the manufacturing organizations, below are the additional difficulties facing by both APQP team members and leader.

- No visibility of PPAP status across various departments

- No workflow control driving the process across the whole APQP process

- Information being difficult to acquire and keep up to date

- Miss communication among APQP / NPI team members

- Too much of paper work

- Trouble finding historic PPAP records

Solutions :

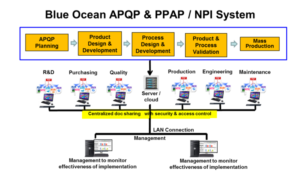

Blue Ocean APQP / NPI system removes these barriers to success by integrating the activities right from planning, product design & development, process design & development, product & process validation and production. This system complies with the requirements of latest ISO/TS 16949: 2016 and ISO 9001:2015 requirements.

Blue Ocean APQP & PPAP / NPI system is a robust, easy-to-use system designed to effectively manage the whole cycle of NPI process. Below are the key features of this system :

- Work flow control whereby user has flexibility to change the work as per specific customer requirements

- Capability to assign responsibility for both NPI leader and members

- NPI leader has full control on project deadline

- Centralized information sharing for effective communication

- Auto email alert on activities due date

- Highly automated project gantt chart without the need of manual updating

- Online PPAP approval and submission

- Comprehensive history tracking

- Capability to setup template of APQP to cater for different product family such as automotive, electronic, oil & gas, aerospace, etc.

- Real time APQP aging report to alert management on potential delay

Key benefits :