Challenges

Factory machinery and facility maintenance is one of the most important activities in any manufacturing organization because it involves management of million or billion dollar asset. Very often we heard management complaining about in proper management of maintenance activities which cause significant losses to the company. Traditional maintenance management which rely heavily on maintenance personnel to keep track the PM due date, manual recording of machine PM history, planning of PM schedule, control of spare part, compilation of maintenance cost, etc is no longer suitable in today highly competitive business environment. World class manufacturing facility shall be managed by using world class maintenance solutions.

Cost of Poor Maintenance

Solutions

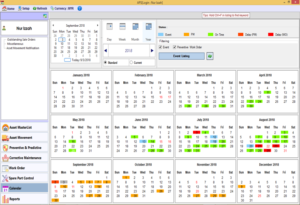

The CMMS helps you organize the maintenance management of your company, keeping all the information of your Maintenance Department documented, updated and organized.Every day, the system reports on the maintenance jobs to be carried out and once they are performed, the system reschedules the following date to do them again, automatically adjusting the maintenance calendars.

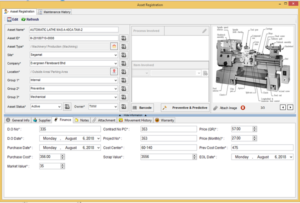

- Document in the system all information related to your equipment and facilities, for example, plans, diagrams, specifications, localization, supplier data, etc.

- Document maintenance plans or routines of each equipment, and automatically create maintenance schedules with the system.

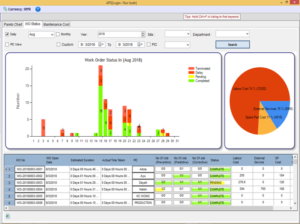

- Automate and simplify the generation, control and follow-up of work orders with the system.

- Maintain full control of the spare parts inventory and reduce inventory levels through the purchase of spare parts just as they are needed.

- Keep all historical information related to works performed and used resources organized and available.

- Generate a large number of reports, indexes and charts related to maintenance management.The versatility of the MP CMMS allows implementing it in any place where there are equipment, machines and facilities subject to maintenance, no matter the size of the company.

Asset Master List

Benefits

- Reduce unexpected shutdowns and emergencies

- Reduce maintenance cost and increase productivity

- Extend equipment’s useful life

- Reduce corrective maintenance costs

- Schedule spare parts acquisition just in time and eliminate stockouts

- Increase reliability and uniformity in production

- Improve maintenance personnel performance

- Avoid accidents

- Organize, standardize and document your company’s maintenance management