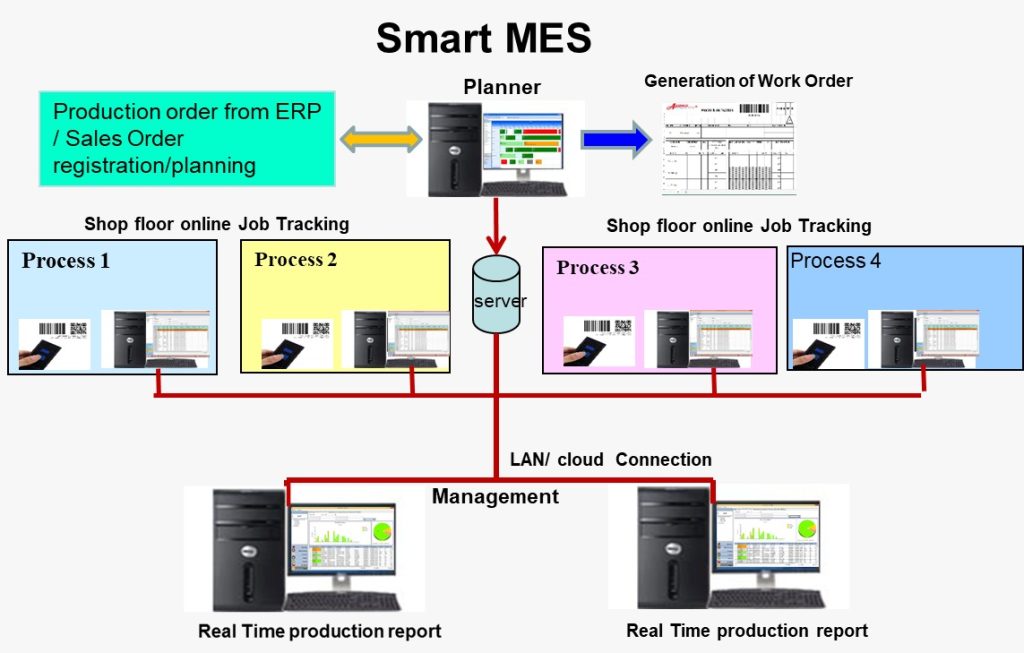

Manufacturing Execution System (MES) by Blue Ocean Data Solutions, designed to help manufacturers transition into Industry 4.0 and Smart Factory 4.0. This advanced, cloud-based Production Execution System integrates seamlessly with ERP systems, SCADA, and PLC controls, enabling real-time production monitoring, automated work order management, and complete shop floor control.

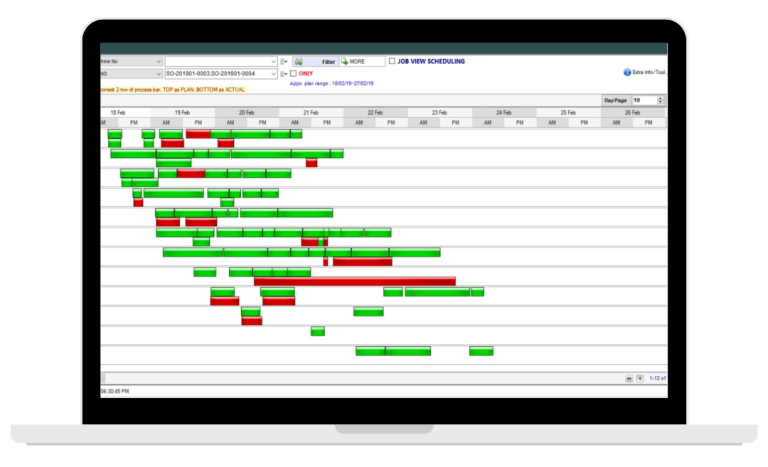

Built for discrete manufacturing, batch production, and high-mix low-volume operations, Manufacturing Operations System delivers end-to-end production visibility, machine connectivity, and paperless workflows. In addition, features such as digital work instructions, quality control modules, inventory management, and OEE tracking reduce cycle time, eliminate manual data entry, and enhance traceability and regulatory compliance.

Furthermore, Smart MES leverages IoT-enabled data collection, AI-driven analytics, and predictive maintenance to optimize operator performance, minimize downtime, and enable faster, data-driven decisions. The web-based MES dashboard provides centralized access to KPIs, downtime analysis, and real-time status updates from any device, anywhere.

Across industries including automotive, electronics, metal fabrication, pharmaceuticals, F&B, and precision engineering, Smart MES offers scalable deployment for SMEs and enterprise manufacturers alike. Moreover, its flexible architecture supports MES–ERP integration, SCADA–MES synchronization, and barcode system compatibility, ensuring smooth deployment across the digital ecosystem.

Ultimately, Smart MES empowers manufacturers to improve operational efficiency, reduce waste, and achieve full digital transformation, making it a future-ready solution for smart manufacturing.