Turning Data

Into Profits

- About

- IR 4.0 Solutions

Production

Engineering

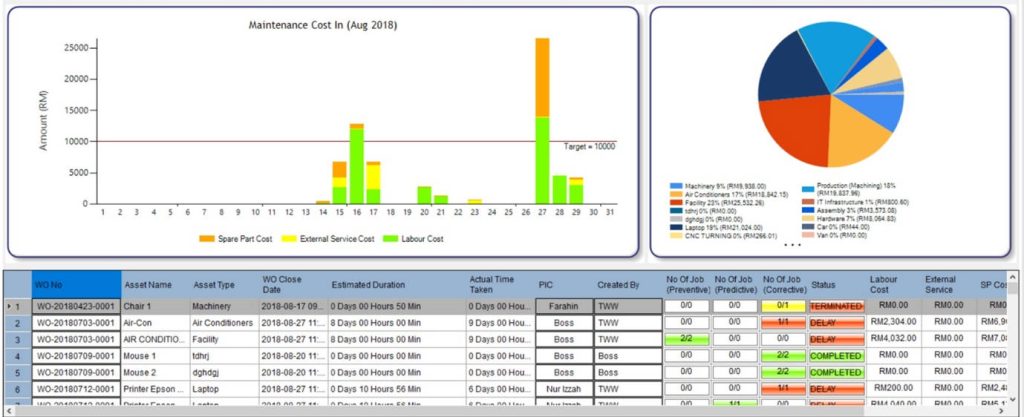

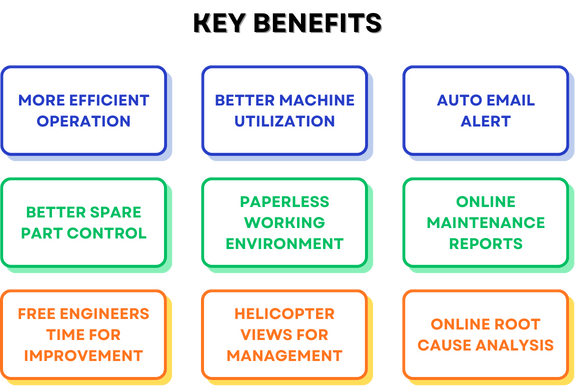

Maintenance

- Case Study

- Resources

- Partners

- Training

- Investment

- IR 4.0 Grant

- Contact

- About

- IR 4.0 Solutions

Production

Engineering

Maintenance

- Case Study

- Resources

- Partners

- Training

- Investment

- IR 4.0 Grant

- Contact