Turning Data

Into Profits

Turning Data

Into Profits

Introduction:

Eight disciplines problem solving methodology is a structured approach which is widely used in manufacturing industry for root cause analysis. It is particularly suitable to solve those complicated quality, process, engineering or operation issues which involves may parties such as suppliers and various departments.

Automotive quality management system (ISO/TS 16949) emphasize on defined process for problem solving leading to root cause identification and elimination. 8D is the most established customer-prescribed problem-solving format (refer to below diagram)

8D Root Cause Analysis Methodology

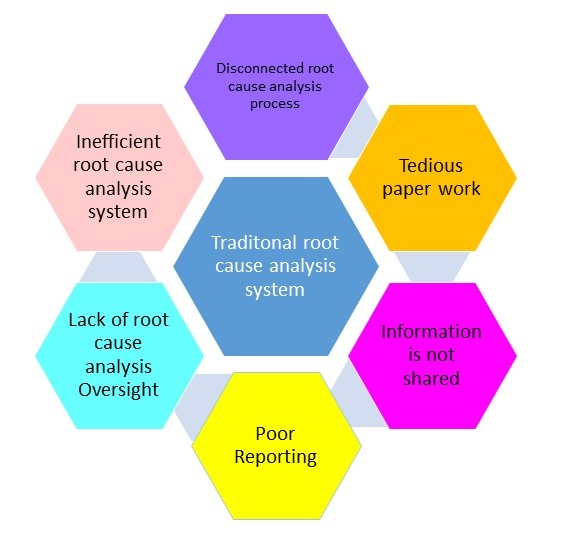

Inefficient and difficult to maintain:

Paper-based and hybrid systems for root cause analysis are inexpensive initially. In the long term, however, these systems are inefficient, requiring tremendous man-hours in terms of routing root cause analysis and other documentation, and manual search and retrieval of documents during verification and audits.

No Integration and information Sharing:

A root cause analysis may be triggered by customer complaints, internal non-conformance, customer claims, internal or external audit, etc.. With manual and hybrid systems, these sources are not connected, making data collection slow and incomplete. Without connectivity, critical information may fall through the cracks, and the root cause investigation is likely to be unreliable

Lack of Root Cause Analysis Oversight

Poor implementation of root cause analysis process is the top reason for issuance of non-compliance during internal or external audit which may stem from the lack of ability to track and monitor open corrective action request and proactively improve the root cause analysis process

Solutions:

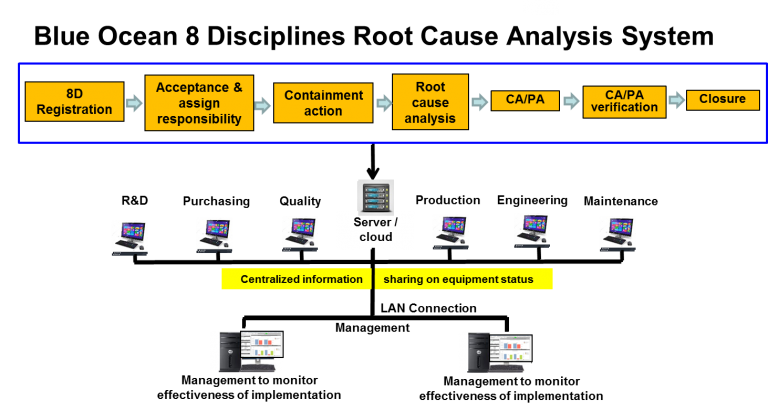

Blue Ocean 8D root cause analysis system is designed by industry practitioners and experienced quality consultant for automating root cause analysis process in any organization.

An automated root cause analysis system reduces audit time and findings, and decreases risk of product recalls. It improves product quality and safety, increases customer satisfaction, and ensures ISO compliance.

Blue Ocean root cause analysis software is a robust, easy-to-use system designed to effectively manage the corrective action / preventive action process and integrate it with other quality processes critical to regulatory compliance, such as change control, audit, and customer complaints.

Real time Reporting:

Blue Ocean Root Cause Analysis system tracks quality incidents that can escalate into a improvement actions. The system provides advanced analytics and reporting capability, including customizable reports and online charting. Through the reports, managers get a real-time view of the root cause analysis process and can be more proactive about improving product quality and profitability of company.

Centralized information management:

The Blue Ocean 8D root cause analysis system automates routing, notification, delivery, escalation and approval of improvement actions and all related documentation. It automates management of entire root cause analysis process, from initiation to investigation and all the way through closure. Provides a secure, centralized, and Web-based repository for all improvement actions documents.

Blue Ocean Data Solutions is a highly experienced company provides turnkey manufacturing solutions. With more than 10 years of experience serving a large customer base in manufacturing and hands-on expertise in programming, software and statistical data analysis combine with six sigma and lean manufacturing methodology, we assist our clients to solve complicated operation problems – yielding profitability increases and driving service and product delivery excellence.

Company

Contact Us